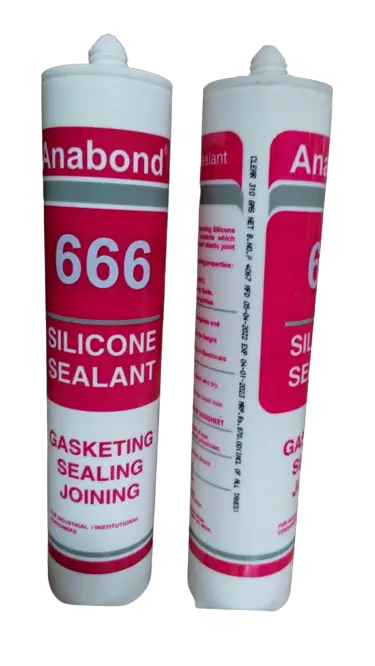

Anabond 666 Silicone Sealant 310 grams New

Original price was: ₹870.00.₹690.00Current price is: ₹690.00.

- Good Thermal stability, Excellent Mechanical properties

- Good Dielectric properties, High Elasticity

- Good weatherability and UV Resistance

- GST Invoice on all orders

- All prices are inclusive of GST

- 100% New & Original Products

- Worldwide shipping available

- Pay with Credit/Debit Card, Netbanking, Wallet & UPI

Description

Anabond 666 Silicone Sealant HSN:3214

Anabond 666 is a single component, non-slumping, low odour, low volatile silicone adhesive/sealant. It is designed to provide reliable “formed-in-place” gaskets for mechanical assemblies where high temperatures are experienced. The material cures on exposure to moisture in the air to form a tough, flexible, silicone rubber gasket. The product resists aging, weathering and thermal cycling without hardening, shrinking or cracking. It has good adhesion to substrates like aluminum, mild steel, glass, ceramics, corks and many plastics.

Anabond Single part RTV(Room temperature Vulcanizing) Silicon systems are ready to use, that cures as resilient silicon rubber at room temperature. These are versatile products which find immerse use in all kinds of industries, offering exceptional properties. It can be used as a adhesive, sealant, F.I.P Gasket.

Anabond 666 Silicone Sealant Features :-

- Good Thermal stability, Excellent Mechanical properties

- Good Dielectric properties, High Elasticity

- Good weatherability and UV Resistance

-

Color: Clear Packaging: Cartridge

Anabond 666 Silicone Sealant Application :-

- Automotive Industries : Used as F.I.P(Form in place) Gasketing sealant for engine assembly such as oil pan, Transmission covers, water pump mounting etc.

- Aircraft Industries : Used as gasket Sealing, Ducting, Vibration, Dampers

- Construction Industries : Used for glass glazing, window perimeter joints, wash basin, bathtub sealing, A/c Duct sealing etc.

Curing performance

The product cures on exposure to moisture in the air, typically developing a skin within minutes, becoming tack free within minutes to hours. After skin formation, cure continues inward from the surface. Optimum physical properties are reached after curing for 7 days at

55±5% RH. The rate of surface/depth cure depends on the relative humidity and temperature of the environment thickness of the adhesive and the area under the joint Curing time is extended at lower humidity levels.

Curing tested at 30 ± 20C, 55 ± 5% RH

Operating parameters for Anabond 666 silicone sealant

- Application temperature ⁰C 10 to 40

- In service temperature ⁰C -50 to +250

- Short exposure ⁰C 275

Directions for use

Substrate preparation

Surfaces to be adhered or sealed should be free of dirt, oil and other contaminants. For best performance clean the surface with a solvent such as isopropyl alcohol acetone or methyl ethyl ketone or with coarse lint free cloth. A surface primer is recommended for hard to bond surfaces, such as some plastics. Apply a thin coat of primer after cleaning the surface with solvent, and allow drying for 5 to 10 minutes at room temperature. Note that the adhesive may not show adhesion to polyethylene, polypropylene, polyacetal or Teflon.

Method of application

Adhesive/sealant can be applied directly from its collapsible tube or extruded from its cartridge. A plastic nozzle is supplied which can be cut to the desired orifice and shape to facilitate application. Apply a continuous bead of adhesive/sealant to prepared surface in a uniform thickness. If spreading is required, use enough pressure to spread the adhesive/sealant and displace any trapped air The adhesive/sealant bead size to be specified is a function of anticipated gap size for the part and the flange width. Consult Anabond representative for equipment supplier and design recommendations.

Dispensing

The product can be dispensed using a manual dispensing gun, Pneumatic dispensing gun or customized dispensers. While using pneumatic

dispensers, the product should be dispensed using 1 or 2 bar pressure. For information on appropriate dispensing equipment, please contact Anabond.

Storage

The optimal storage condition is 8°C to 30°C. Storage below or more than the temperature specified, has impact on the product properties.

Material removed from containers may be contaminated during use. Do not refill the product to the container. Sealant cures by moisture. Keep the container tightly closed when not in use. A plug of cured material may form in the tip of tube or cartridge, which can be easily removed and will not affect the remaining contents.

Shelf life

When stored at or below 300C, in the original unopened containers, this product has a shelf life of 18 months from the date of manufacture.

Product Documentation: Click Here.

Shop more products from Anabond: Click Here.

Additional information

| Country of Origin | India |

|---|---|

| Brand | |

| MPN | 666-CLEAR-310G |

Only logged in customers who have purchased this product may leave a review.

Loctite 222 Threadlocker Low Strength, 50ml

Loctite 222 Threadlocker Low Strength, 50ml

Reviews

There are no reviews yet.